Service

Découpe couteau basé à Toulouse

Price of the Service

Category of the Service

Company website

Our recommended products and services

-

-

FLAME CUTTING Flame cutting is a process for cutting larger steel thicknesses of steel. In order to obtain a sufficiently high temperature for flame cutting, a cutting torch is used which differs from a welding torch in that it has an additional supply of pure oxygen through a special nozzle. The largest use of flame cutting takes place in the heavy steel industry, where the good cut quality in flame cutting is used for welding joints. The cutting speed in thin sheets is not as high as with plasma or laser cutting, but for larger wall thicknesses, flame cutting is fastest.

-

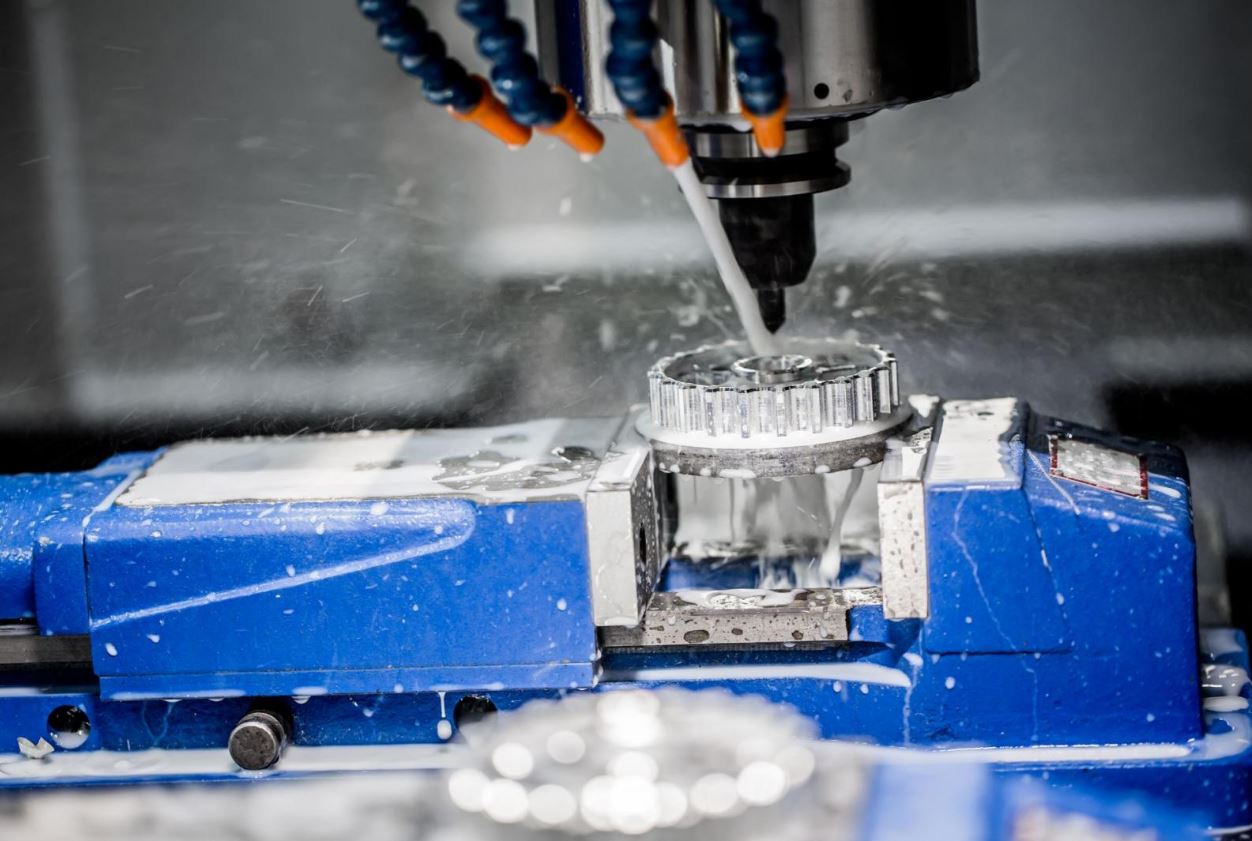

Micro-waterjet cutting is a variant of conventional waterjet cutting that is capable of carrying out high-precision cuts of a very small size, while maintaining the main advantages.

-

Waterjet cutting allows us to cut any type of material Advantages of the process: · It is a cold cut in which the properties of the material do not vary. · Capable of cutting in thicknesses up to 200 mm. · Access to manufacture very complex geometric shapes. · It does not create tensions in the finished piece. · In many cases the cut piece does not need any type of finish. · It is an environmentally friendly process, because it does not emit gases or dusts into the air.

-