Product

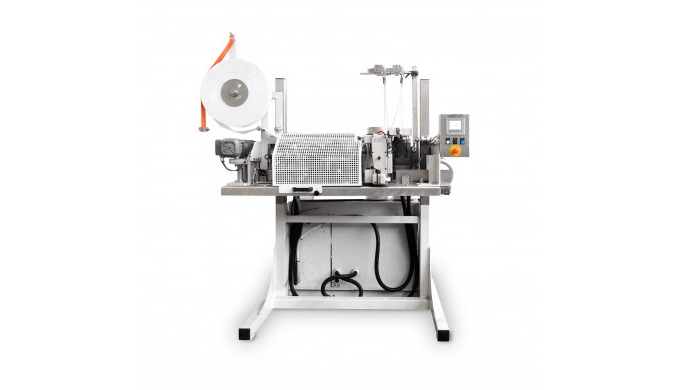

Over Tape Bag Sealer: Bag closing system

A woven PP tape is used for a reliable and secure closure. If necessary, the bags can also be sewn. Both pillow bags and gusset bags can be securely closed. This sealing technology facilitates the handling of dusty and odour-intensive products of the food and feed industry.

During operation, the filled bags are transported to and from the bag closing system via a conveyor belt. A sensor detects the position of the bag and automatically puts it into the trimming area. After cutting the top edge of the bag a woven PP tape is applied over the open edge of the bag to seal it with hot air. The hot air to seal the bag airtight and odourless is produced by a heating unit in the machine.

- Capacity : up to 1500 bags/hour .

- Bag type : pillow bag and gusset bag .

- Bag material : woven PP-bags .

- Air pressure : 6 bar, constant, dry and oil free .

- Air consumption : ~20 Nm3 /h .

- Power supply : 3 x 380 – 480 VAC, 50/60 Hz, PE .

- Protection class : min. IP54 .

- Power consumption : ~ 6.0 kW .

Price of the Product

Category of the Product

Company website

16

products -

STATEC BINDER GMBH

Company catalogues - STATEC BINDER GMBH