Product

CNC/SPM Turning and Threading Machine

Turning ThreadingFeatures:

- Machine is used for turning,facing,parting,threading,taper turning,chamfering and grooving material.

- Pneumatic Clamping with Collet or Chuck.

- Developed software as per indian market requirement

- High production rate.

- It can operate by unskilled persion.

- User Friendly Operations.

- Low Maintenance cost.

- Easy to service.

- Run on Very High Speed FPGA based Motion Control Card

- High efficiency.

- Accuracy: The min error of 0.01mm.

- Automatism and convenience: Simple software hardware installation, operate the manufacturing process by pressing touch screen button.

Price of the Product

Technical Details

X,Y working area - 250x250mm

X,Y structure - Linear Ball screw

Z structure - Spindle

Max. speed - 6000 mm/min

Spindle speed - 1000 -3000 RPM

Operating system - WINDOWS XP/7

Accuracy - 0.010mm

Resolution - 0.018mm

Production - 2000 pcs per day

Diameter Rang - 5 mm to 100 mm

Number tool post slots - 4

Power requirement - 3 Kw

Live Tooling - Yes

Auto Door - Yes

Operation - Turing,Threading,Facing,Chamfering,Taper Turning,Parting & Grooving.

Weight - 1350 kgs

Size - 1.5 X 1.2 X 1.8 Meter

Category of the Product

Company website

3

products -

Vision Embesoft Solution

Our recommended products and services

-

-

EFCO TD-CNC: Precision and Flexibility in Portable CNC Machining High-Precision CNC Facing and Boring Machines EFCO’s portable CNC facing and boring machines are ideal for precise surface machining of industrial valves and complex components. Their large axial stroke allows deep machining, perfect for bores and sealing surfaces. Extended Machining Depth Optional accessories enable machining depths beyond standard limits, ensuring greater flexibility for demanding applications. Easy to Use – No Programming Skills Required More than 10 pre-installed standard programs cover common machining cycles, allowing users to start work immediately, without programming knowledge. Customized CNC Programs The integrated SIEMENS CNC control ensures high precision. Programs can be tailored to customer needs but are set up by EFCO. - : .

-

Control Lathe, Number DAEWO PUMA 350B, 500,x 1000 Parallel Lathe, LACFER, 400,x 1000 Pick-up Lathe,MORISEIKI CS200/250,350,x 150 Control Lathe,Numric MORISEIKI SL300B/700,450,x 700 Control Lathe,Numer MORISEIKI SL200/500,300,x 500 Vertical Lathe,Numerical Control DAEWO PUMA-V550M,800,X=490 Z=780 Lathe CMZ TBI-520,MC,Ø360×1000

-

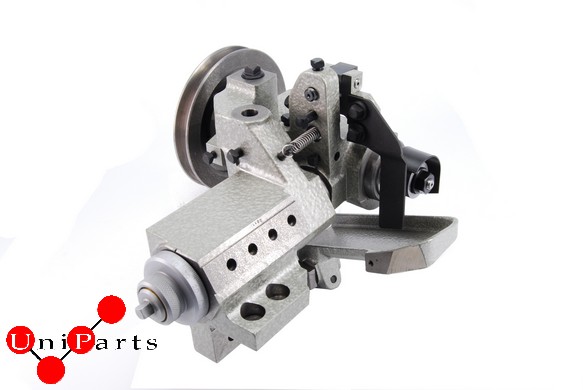

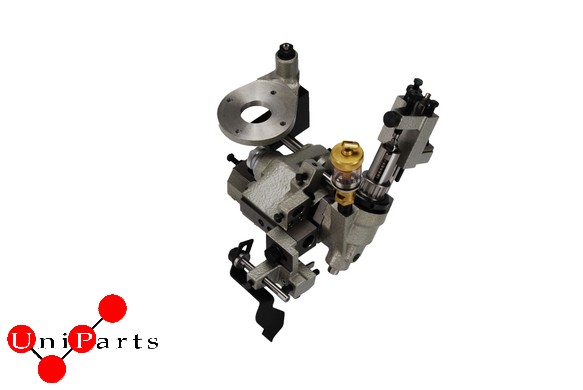

Slotting attachment type 14EA for Automatic LathesTornos

-